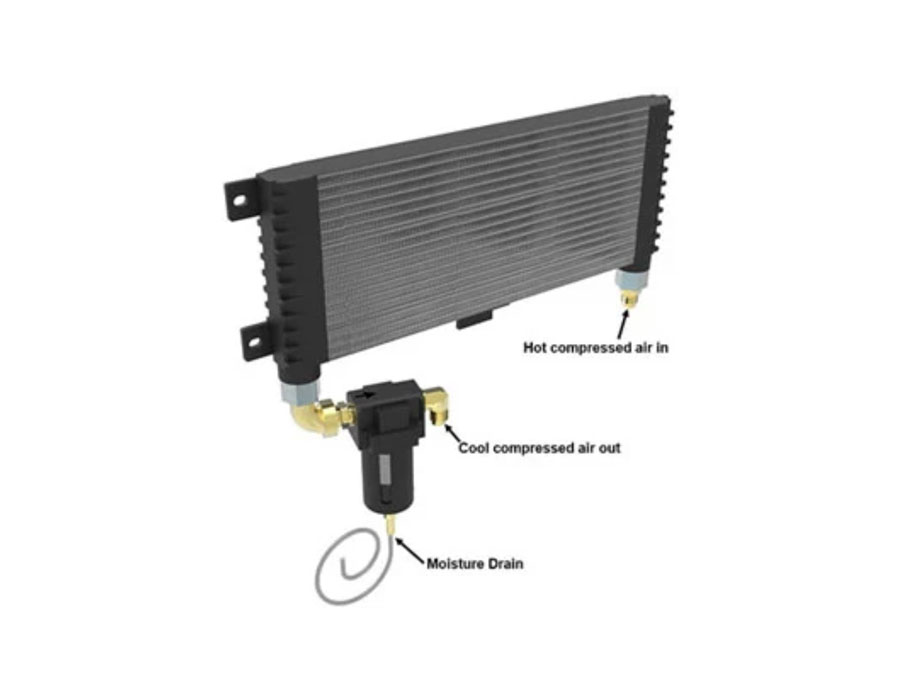

The Introduction About Screw Air Compressors

Screw Air Compressors are two types of air compressors, single and twin screw. The invention of twin-screw air compressor is more than ten years later than single-screw air compressor, and the design of twin-screw air compressors is more reasonable and advanced. The twin-screw air compressor overcomes the shortcomings of single-screw air compressor which is unbalanced and the bearings are easily damaged, and has the advantages of long life, low noise and more energy saving. After the technology matured in the 1980s, the scope of its application is expanding day by day. It has become an inevitable trend to replace the piston air compressors with Screw Air Compressors which have many wearing parts and poor reliability. Screw air compressors have the advantages of simple structure, small size, no wearing parts, reliable work, long life and easy maintenance. Single-screw air compressor, also called worm gear air compressor, the meshing vice of single-screw air compressor consists of a 6-head screw and two 11-tooth star wheels. The worm is engaged with two star wheels at the same time, which makes the worm balanced and doubles the displacement, and the volume of the compressor is small, only 9 cubic meters per minute (9 m3/min).

The advantages Of Screw Air Compressors

There exists some advantages of screw air compressors: High performance and high efficiency: The air compressor equipment - screw air compressor adopts high capacity compression components with low rotor peripheral speed and optimum oiling, achieving high efficiency and high reliability. As of 2012, the manufacturer's design ensures extremely low system temperatures and compressed air temperatures. All components are guaranteed to achieve optimum cooling and maximum service life.

Drive concept: The air compressor plant - screw air compressor - drives the compressor unit at the optimum speed for the application by means of an efficient drive system. It is completely maintenance-free during normal operation. Maintenance-free, highly reliable and highly efficient.

Low maintenance: The original compressor design of the air compressor plant-screw air compressor saves unnecessary maintenance costs. All components are designed for long life, and large inlet filters, oil filters and fine separators ensure optimum compressed air quality. All oil filters and separator components for all models up to 22kW (30hp) are centrifugal opening and closing, further reducing maintenance time. Maintenance can be completed in minutes, reducing downtime and maintenance costs.

Built-in intelligent control: sophisticated operating controls are essential to reduce operating costs. All screw compressors are equipped with an intelligent control system with easy-to-use control menus.