Compressor Air Aftercooler

Air compressor aftercoolers play a crucial role in maintaining the quality of compressed air by removing heat and moisture from the compressed air stream. In this article, we will explore the significance of aftercoolers, delve into the two most common types, and highlight their vital role within an air compressor system.

What Exactly is an Aftercooler?

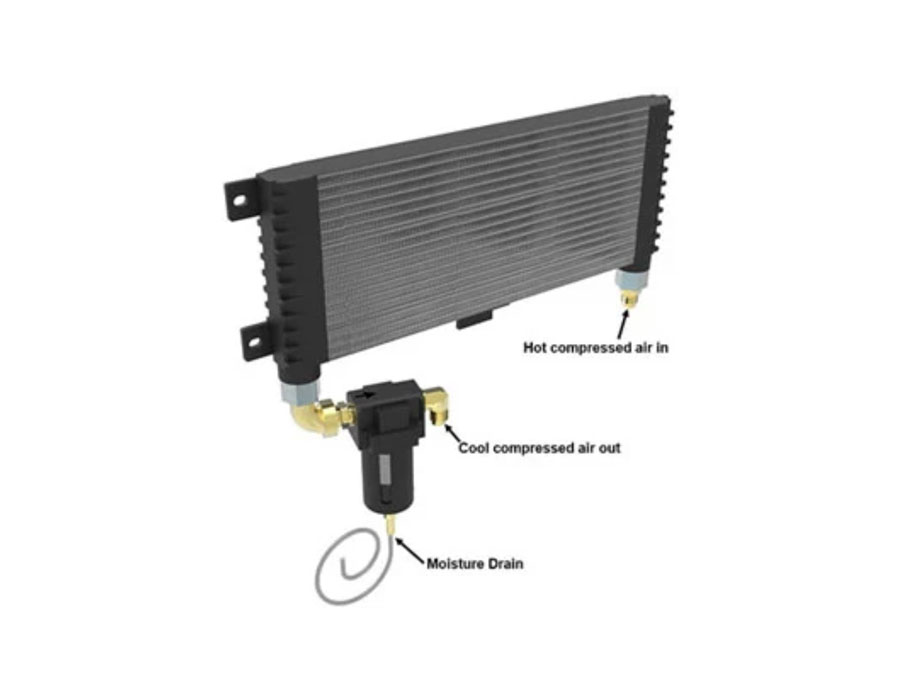

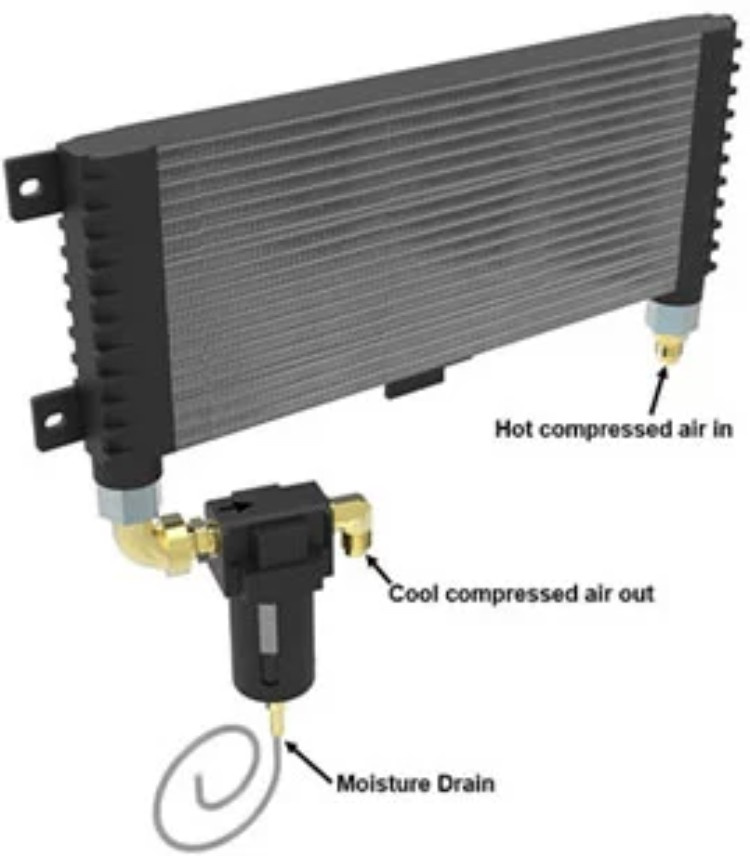

An aftercooler can be defined as a mechanical heat exchanger specifically designed to cool and dehumidify compressed air, ensuring it reaches an optimal temperature and moisture level for use in air-operated equipment.

Primary Functions of Compressed Air Aftercoolers:

Cooling: The foremost function of an aftercooler is to cool down the air discharged from the air compressor. When compressed air is generated, it tends to be hot, and the aftercooler helps in reducing its temperature to a more suitable level.

Moisture Reduction: Compressed air contains a significant amount of moisture, which can adversely affect downstream equipment and processes. Aftercoolers aid in minimizing the moisture content in compressed air, making it more suitable for various applications.

Equipment Protection: Excessive heat and moisture can cause damage to downstream equipment. Aftercoolers act as a protective barrier, preventing potential harm by maintaining the air temperature and moisture levels within acceptable limits.

Why Are Air Aftercoolers Necessary?

It is important to understand that compressed air discharged from an air compressor is inherently hot. The exact temperature of the compressed air will vary depending on the type of compressor utilized. However, regardless of the compressor type, aftercoolers are essential to ensure the compressed air is cooled down before it is utilized.

Exploring the Two Common Types of Aftercoolers:

Air-Cooled Aftercoolers:

Air-cooled aftercoolers utilize the surrounding ambient air to cool the compressed air. The compressed air enters the aftercooler and passes through either a spiral finned tube coil or a plate-fin coil design, while a motor-driven fan forces ambient air over the cooler. This process facilitates heat transfer and effectively cools the compressed air.

To remove the condensed moisture, most air-cooled aftercoolers are equipped with a moisture separator installed at the discharge. The moisture separator employs centrifugal force and, in some cases, baffle plates to collect moisture and solids, which are subsequently removed using an automatic drain. Belt guard air-cooled aftercoolers, which are mounted to the compressor's v-belt guard, are commonly used in this configuration.

Water-Cooled Aftercoolers:

Water-cooled aftercoolers are frequently employed in stationary compressor installations where a cooling water source is readily available. There are several advantages to using water as the cooling medium. Water exhibits minimal seasonal temperature fluctuations, is cost-effective, and can efficiently approach the ambient air temperature, thereby preventing condensation downstream.

One prevalent type of water-cooled aftercooler is the Shell and Tube aftercooler. This design consists of a shell with a bundle of tubes inside. Compressed air flows through the tubes in one direction, while water flows through the shell in the opposite direction. Heat from the compressed air is transferred to the water, causing liquid water to form within the tubes. Similar to air-cooled aftercoolers, moisture is removed through a moisture separator and drain valve.

In conclusion, air compressor aftercoolers are essential components in maintaining the quality of compressed air. By effectively cooling and dehumidifying the air, they protect downstream equipment and ensure optimal performance. Whether utilizing air-cooled or water-cooled aftercoolers, the importance of these devices cannot be overstated in the realm of air compressor systems.

Jiusheng Air Aftercooler

Jiusheng offers various types air aftercooler options for screw air compressors and other air compressors. Supporting Customization, pls send your requirements, we provide OEM and ODM Service. Both aftercooler models were designed to improve air performance and extend the life of air tools by removing up to 80% of the moisture from compressed air.