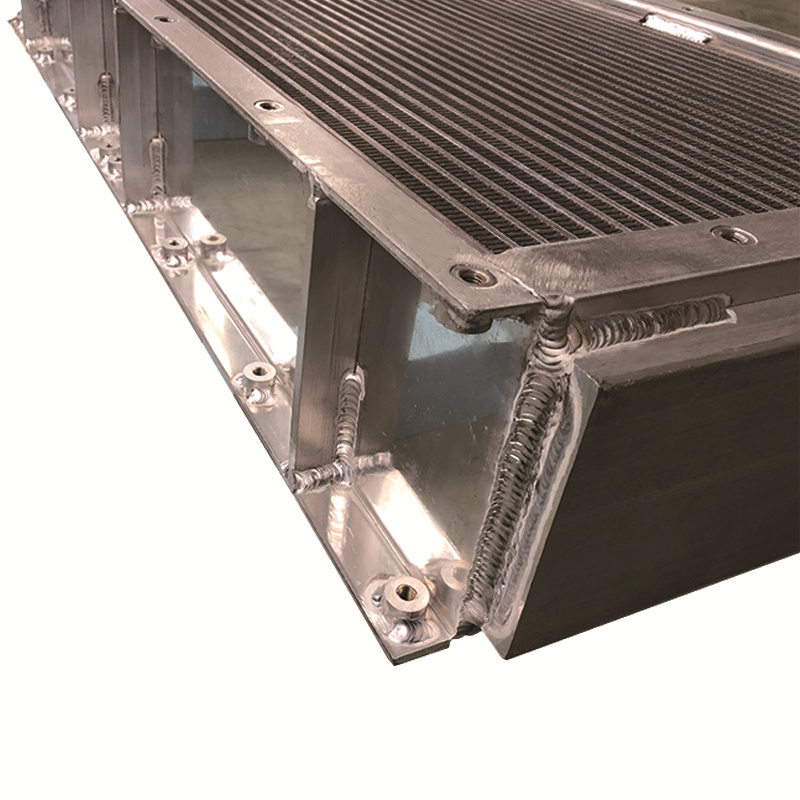

I-Plate Fin yoTshintshiselwano loBubushushu boMzi-mveliso waMandla omoya Amandla amatsha

Ingcaciso yeMveliso

Sinomthamo omkhulu wemveliso kunye nolawulo olungqongqo lwekhwalithi. Iisinki zethu zobushushu zithobela imigangatho yamazwe ngamazwe kwaye zisetyenziswa ngokubanzi ngabavelisi abakhulu beeinjini zomoya. Xa kuthelekiswa neesinki zobushushu zentsimbi yesiko, iisinki zethu zobushushu ze-aluminium ezikhutshiweyo zibonelela ngokusebenza okuphezulu, ukuqina kunye nokusebenza kakuhle kweendleko. Ukuba ujonge iisinki ezithembekileyo ze-injini yomoya, qhagamshelana nathi namhlanje!

Inkcazo

Igama lemveliso | I-Plate Fin yoTshintshiselwano loBubushushu boMzi-mveliso waMandla omoya Amandla amatsha |

Ulwakhiwo | I-Plate Fin yokuTshintsha ubushushu |

Iintlobo zokugqibela | Iphiko elingenanto, iphiko elipheleleyo, iphiko eligqojoziweyo, iphiko eligobileyo, iphiko eligobileyo |

Umgangatho | CE.ISO,ASTM.DIN.etc. |

Phakathi | I-oyile, uMoya, Amanzi |

Izinto Ezigqibelele | 3003 Aluminiyam |

Izinto zetanki | 5A02 iAluminiyam |

Uxinzelelo lokusebenza | 2-40 Bar |

Ubushushu be-ambient | 0-50 Deg C |

Ubushushu bokusebenza | -10-220 Deg C |

Izizathu zokukhetha iimveliso zethu

Ukuthembeka kwesiqinisekiso

I-Aluminiyam ipleyiti yohlobo lomoya amandla omoya omtsha weradiyetha yenziwe ngemathiriyeli ye-aluminiyam esemgangathweni ophezulu, emva koyilo olungqongqo kunye novavanyo lovavanyo, ukuthembeka kwayo kuqinisekiswe kakuhle. Njengenxalenye ebalulekileyo yezixhobo zamandla omoya, i-radiator kufuneka isebenze kwindawo enzima ixesha elide. Siye saqhuba uvavanyo lokudinwa kokunyamezela, uvavanyo lokudinwa kweqondo eliphezulu neliphantsi kunye nezinye iimvavanyo kule mveliso, eziqinisekisa ngokupheleleyo ukusebenza kwayo okugqwesileyo kunye nobomi benkonzo ende phantsi kweemeko ezahlukeneyo ezinzima. Ukongezelela, sikwabeka iliso kwi-radiator ekusebenzeni kwisayithi, kwaye iziphumo zibonisa ukuba ukusebenza kwayo kuzinzile kwaye inokwethenjelwa. I-conductivity ephezulu ye-thermal kunye neempawu ezibalaseleyo ze-aluminium ziqinisekisa ngokufanelekileyo ukusebenza kwexesha elide kwe-radiator. Abathengi banokuyisebenzisa ngokuzithemba ngaphandle kokukhathazeka ngeengxaki zekhwalithi, eyona nto iyinzuzo enkulu yale mveliso kwintsimi yamandla amatsha.

Ukukwazi ukwenza ngokwezifiso

Iiradiyetha zethu ze-aluminium plate fin zenzelwe ukuba zenziwe ngokwezifiso kungekuphela nje kwiiparitha zemodeli ezithile ezibonelelwa ngumthengi, kodwa kunye nendawo yofakelo kunye nemeko yokusebenza yeeinjini zomoya ezahlukeneyo. Ukongeza, sinokubonelela ngeenkcazo ezahlukeneyo kunye neemodeli zeemveliso kubathengi ukuba bakhethe ngokobungakanani bemveliso yomthengi kunye neemfuno zokutshatyalaliswa kobushushu. Oku kwandisa kakhulu ububanzi besicelo kwintsimi yamandla amatsha.

Ukunyangwa kokuMhlwa

I-Aluminiyam ipleyiti yohlobo lomoya womoya weradiyetha yamandla amatsha yenziwe ngemathiriyeli ye-aluminiyam ekumgangatho ophezulu, enokumelana nokugqwesa okugqwesileyo. Njengenxalenye ephambili yezixhobo zamandla omoya ezisebenza kwintsimi ixesha elide, i-radiator ijongene nomngcipheko womonakalo obangelwa yimimandla eyahlukeneyo yendalo enzima. Nangona kunjalo, imveliso isebenzisa i-alloy ye-aluminium kunye nokumelana nokuqina kwe-corrosion, kwaye emva konyango lokukhusela ngononophelo, inokumelana ngokufanelekileyo nefuthe lemithombo eyahlukeneyo ye-corrosion efana netyuwa yolwandle kunye nemvula ye-asidi, kwaye inokusebenza ngokuzinzileyo kwiindawo ezahlukeneyo ixesha elide.