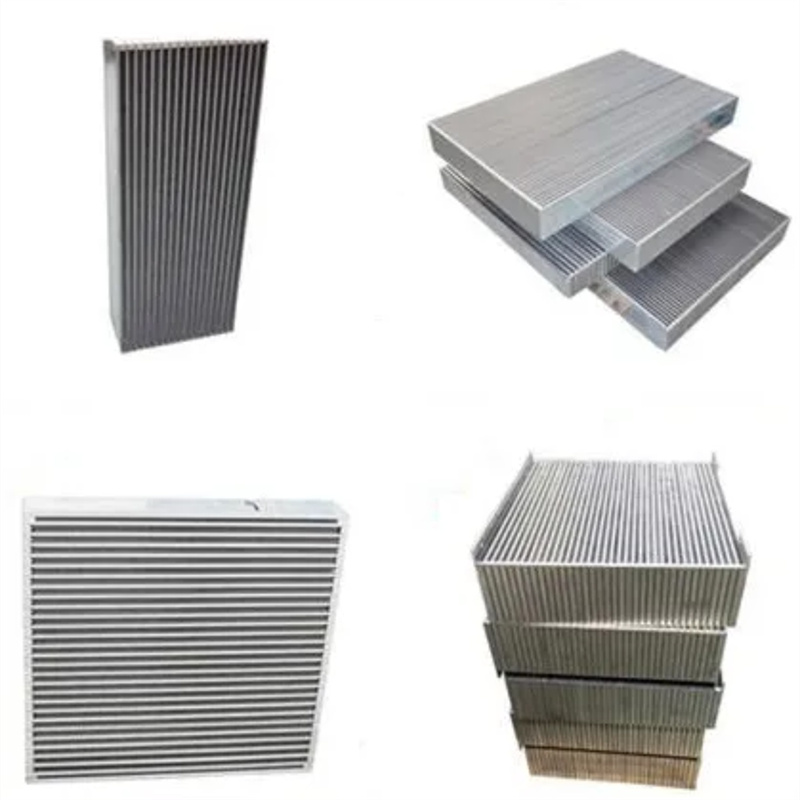

I-Intercooler Core Cooling System yeAluminiyam yePleti Fin Heat Exchanger ipleyiti yokupholisa ioli

Ingcaciso yeMveliso

Senza ngokwezifiso ii-alloys, imilinganiselo, ulungelelwaniso, kunye nokunyuswa ukuze kuhambelane neemfuno zakho. Qhagamshelana neengcali zethu zobugcisa ukuhlaziya iinkcukacha zeprojekthi yakho kunye neemfuno zolawulo lobushushu. Sinikezela ngezisombululo ezingabizi kakhulu kunye neziqinileyo zealuminiyam ezakhelwe ukujongana nemiceli mngeni yakho yokupholisa.

Inkcazo

Igama lemveliso | I-Intercooler Core Cooling System yeAluminiyam yePleti Fin Heat Exchanger ipleyiti yokupholisa ioli |

Izinto eziphathekayo | Aluminiyam ingxubevange 3003/5A02/6061 |

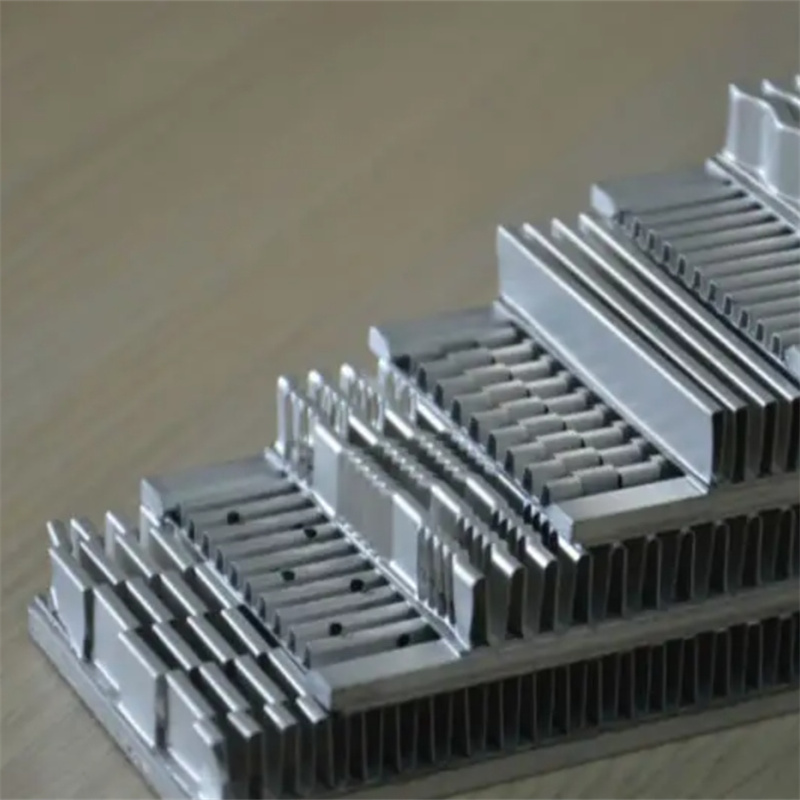

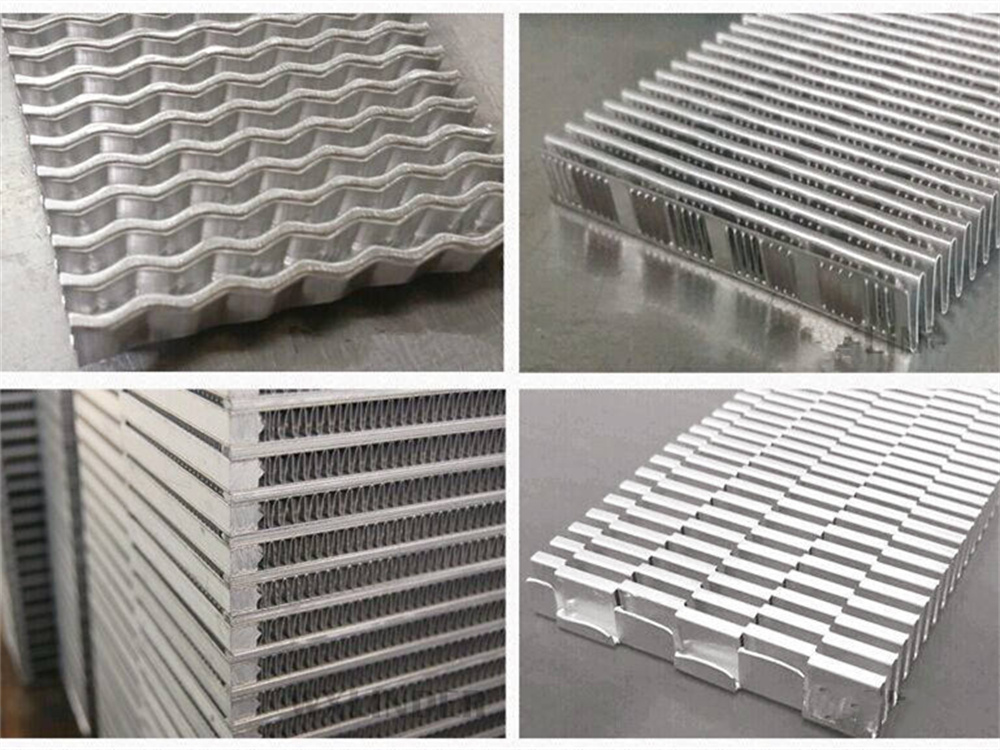

Iintlobo zokugqibela | Iphiko elingenanto, iphiko elipheleleyo, iphiko eligqojoziweyo, iphiko eligobileyo, iphiko eligobileyo |

Umgangatho | CE.ISO,ASTM.DIN.etc. |

Phakathi | I-oyile, uMoya, Amanzi |

Uxinzelelo lokusebenza | 2-40 Bar |

Ubushushu be-ambient | 0-50 Deg C |

Ubushushu bokusebenza | -10-220 Deg C |

Izizathu zokukhetha iimveliso zethu

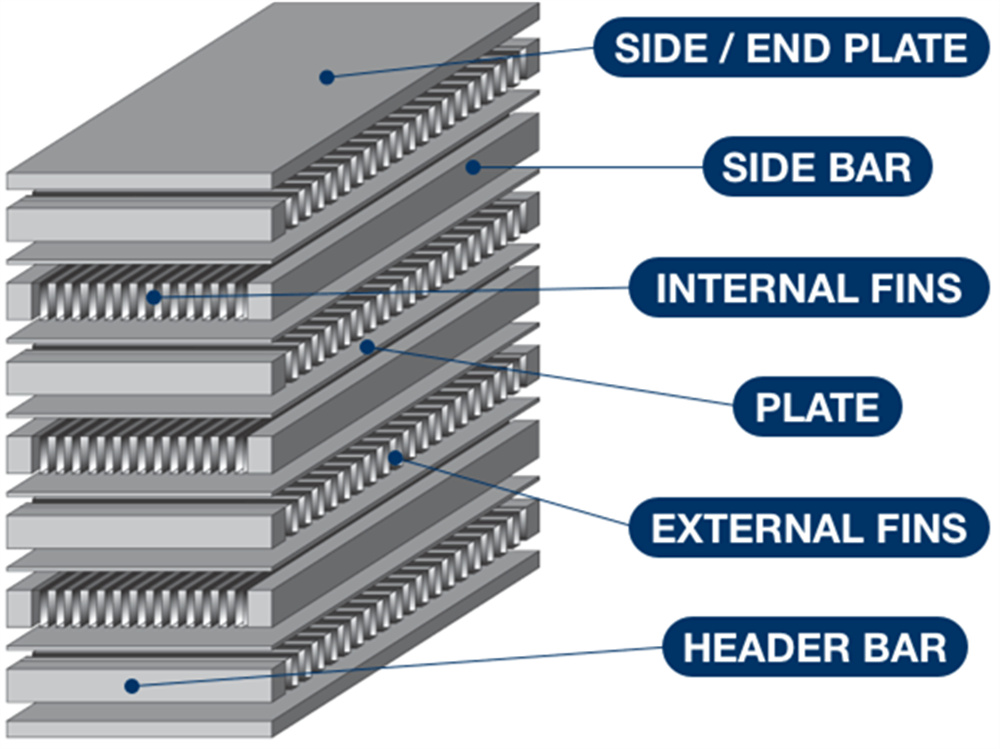

Ukukwazi ukwenza ngokwezifiso

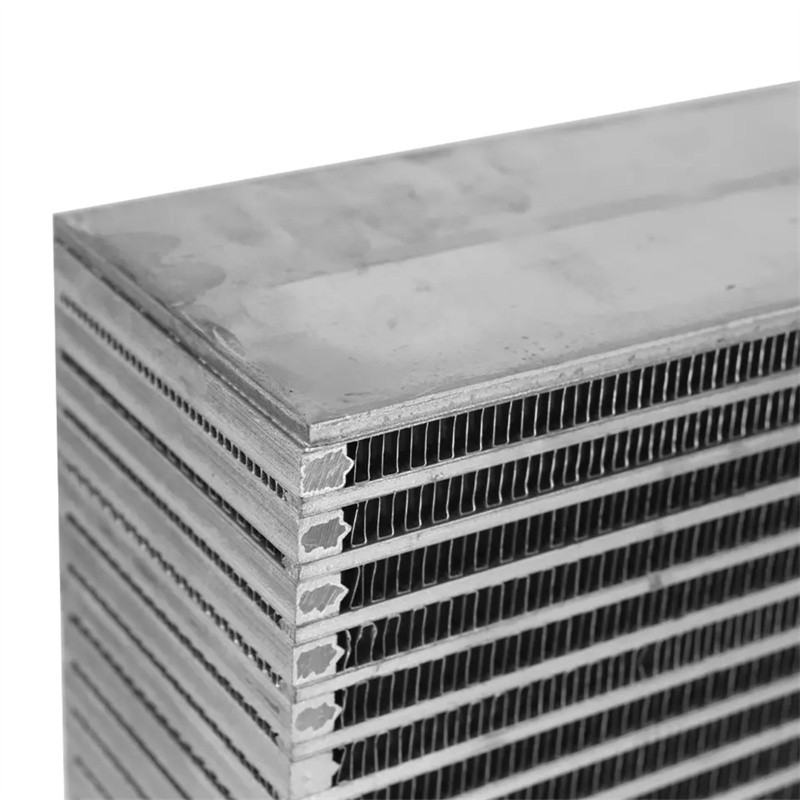

Uyilo lwemodyuli, ngokweemfuno zabathengi, indibano elungiselelweyo yeenkcazo ezahlukeneyo zesiseko sokutshatyalaliswa kobushushu kunye neempumlo, ukufezekisa inani lamashaneli, isakhiwo sesiko. Ubungakanani be-interface inokuthi yenziwe ngokuchanekileyo kwaye yenziwe ngoomatshini ngokweeparamitha kunye neemfuno zobungakanani bezixhobo zabathengi. Ngexesha elifanayo, ngokusetyenziswa kweendawo ezahlukeneyo, unokukhetha izixhobo ezahlukeneyo kunye nokuphathwa kwendawo, ukusebenza kwe-anti-corrosion ye-radiator core. Ingubo esebenzayo kumphezulu wangaphandle inokuphinda iphinde ihlaziywe ngokweemfuno zabathengi.

Iqela lamava

Sineqela elinamava lophuhliso lwesisombululo se-thermal esineminyaka engaphezu kwe-10 yamava kuyilo lwe-heat sink kunye nezicelo. Bayakwazi ukubonelela ngohlalutyo lobuchwephesha kunye neengcebiso malunga nezisombululo ezisebenzayo kumngeni wokupholisa abathengi.

Ukongeza, iqela lenkonzo yokuthengisa kunye nezobugcisa liqokelele amava omsebenzi angaphambili, kwaye linokubeka iimbono zobuchwephesha kwiiparamitha zesiko kunye nokusetyenziswa kwendawo yeemveliso, ukwenzela ukuba iimveliso zeradiyetha ezilungelelanisiweyo zikwazi ukuziqhelanisa ngcono neemodeli zabathengi.

Iimeko zokuphunyezwa kweeprojekthi ezityebileyo zenza ukuba iqela liqokelele izisombululo kwiingxaki ezinzima zokutshatyalaliswa kobushushu, kunye nokuphuhliswa kwemveliso emitsha kunye nokulungiswa kakuhle. Ukuphendula kwiimfuno zabathengi ngexesha elifanelekileyo.

Ukuthembeka kunye nokuzinza

Iimveliso ezilungiselelwe yinjineli yobuchwephesha boyilo, ukuchaneka kweCNC machining, ukuqinisekisa ukuba iiparamitha eziphambili zesiseko sokulahla ubushushu zihambelana ngokuchanekileyo, ukuphucula kakhulu ukuthembeka kwemveliso. Ngokuqinisekiswa okungqongqo, i-aluminiyam i-radiator cores jikelele ibonisa ukuthembeka okuphezulu kunye nokuzinza. Kukulungele ukuba abathengi bafumane ukusebenza okuzinzileyo kunye nexesha elide le-thermal.