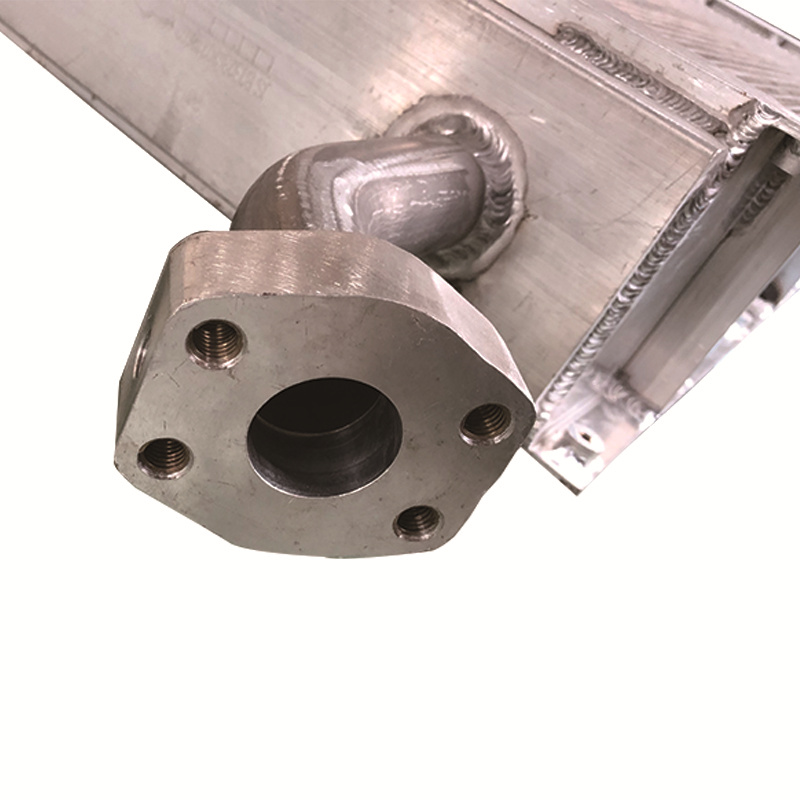

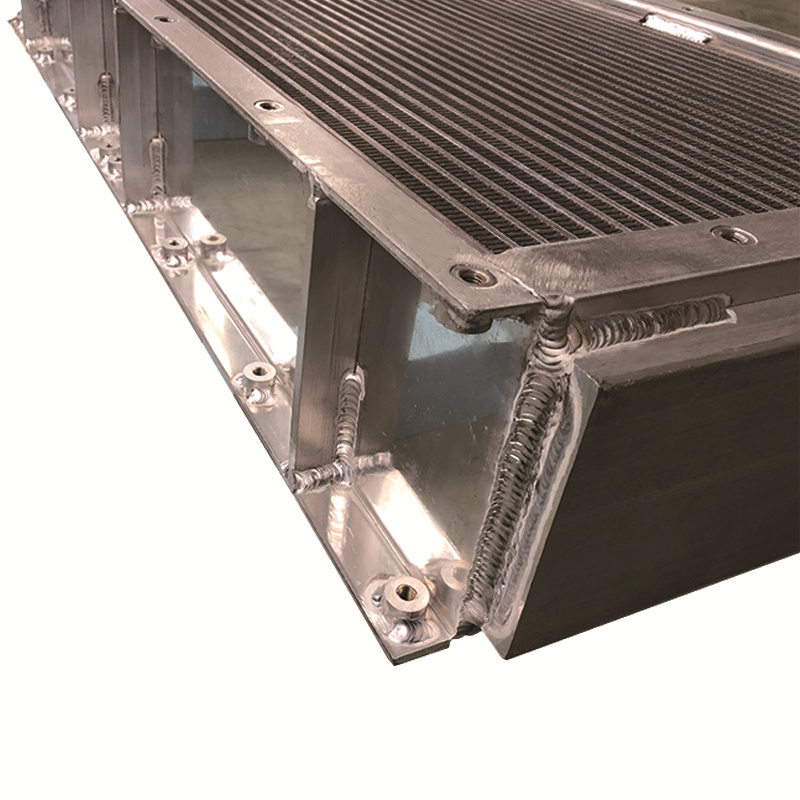

Aluminum plate-fin heat exchanger for wind turbines

Fits For Models

With large production volumes and stringent quality control, we supply heat sinks proven for reliability and cost-effectiveness compared to traditional sheet metal types. Widely trusted by leading wind turbine companies globally, our customers benefit from our expertise in customization. Contact us today to discuss your cooling challenges – we can develop high-performance and durable solutions to ensure safe, efficient operations of your wind power electronics.

Specification

Product name |

Aluminum plate-fin heat exchanger for wind turbines |

Structure |

Plate Fin Heat Exchanger |

Fin types |

Plain fin, Offset fin, Perforated fin, Wavy fin, Louvered fin |

Standard |

CE.ISO,ASTM.DIN.etc. |

Medium |

Oil,Air,Water |

Fin Material |

3003 Aluminum |

Tank material |

5A02 Aluminum |

Working pressure |

2-40 Bar |

Ambient temp |

0-50 Deg C |

Working temp |

-10-220 Deg C |

Reasons To Choose Our Products

Efficient heat dissipation

Aluminum plate fin type wind power new energy radiator adopts lightweight high-quality aluminum alloy material, fin design is compact and efficient, greatly improving the heat dissipation area. Advanced structural design and carefully selected materials make it have extremely high thermal conductivity, which can quickly absorb the waste heat generated by wind turbines and then quickly diffuse outward through fins to achieve efficient heat dissipation of equipment. This not only reduces the temperature of the wind turbine, but also improves the reliability and power generation efficiency of the system.

Corrosion resistance

Wind power new energy radiator is made of high-quality corrosion-resistant materials with excellent corrosion-resistant ability. As an important part of wind power equipment, the radiator is facing the risk of corrosion when it works in harsh outdoor environment for a long time. The wind power new energy radiator with high corrosion resistance design can effectively resist corrosion damage and operate stably in various complex environments for a long time. This helps to reduce scrap parts, prolong the service life of the equipment, and greatly reduce maintenance costs. The outstanding corrosion resistance of the product is one of its important competitive advantages in the field of new energy.

Customization ability

As an important component, the specification size of the radiator directly determines whether it can be applied to different types and power levels of wind turbines. Our radiator products are flexible in design and can be customized not only to the size requirements of the customer's specific wind turbine, but also to different wind farm Working environments and operating conditions. For example, technical parameters such as pipe diameter rules, segment gaps, fin shapes, etc., can be customized to meet the heat dissipation requirements under different altitudes and climatic conditions. This means that our new wind energy radiator products can well meet the personalized and differentiated customization needs of customers, suitable for different specifications of wind turbine, so as to obtain a wider application prospects. Its excellent customization ability greatly expands the application scenarios of the product, which is also an important market advantage for us.